Plywood Manufacturing

Plywood is made by laminating thin sheets of veneer together with the adjoining laminates at right angles to each other. This produces a sheet-like product with grain running in both of the principal directions in the plane of the sheet.

An odd number of laminations is usually used with each veneer laid up at right angles to the previous one. This gives a sheet with just more than 50% of the fibres in the main direction (the face grain direction) and just less than 50% at right angles to that direction as shown.

:

:

Panel Grades

Plywood panels for structural use are available in three grades, identified by a designation of the intended end use.

-

Sheathing (Sheathing Span*) is intended for use as covering material for roofs, sub floors, and walls.

-

Structural 1 Sheathing (Structural 1 Sheathing Span*) meets additional requirements for cross-panel strength and stiffness; it serves in panelized roof systems, diaphragms, and shear walls.

-

Single Floor Panels (Floor Span*) are used as a combination subfloor and underlayment, under carpet and pad, meeting requirements that are more stringent than for sheathing grades.

Standard sizes (mm)

Plywood is available in several lengths and widths and a wide range of thicknesses. Non-standard panel sizes are available on request from manufacturers. However, the most common plywood panel dimensions (mm) are 2400 x 1200 and 2700 x 1200mm .

Sheet sizes (mm) for plywoods include:

2400x1200

2400x900

2100x1200

2100x900

1800x1200

1800x900

2700x1200

A 2250 mm length panel is often specified for flooring applications, as this size suits the standard floor joist spacing of 450mm. Flooring plywood is usually supplied with a plastic tongue and grooved long edges.

Plywood wall bracing is available in 2440 mm and 2745 mm lengths to preserve 2400 and 2700 floor to ceiling height after installation of ceiling and flooring.

Standard thickness: (mm)

Plywood thickness will vary with manufacturer and product application. Standard panel thicknesses range from 3 mm up to 32 mm.

Structural 3, 4, 4.5, 6, 7 12, 13, 15, 17, 19, 21, 25,32mm

Marine, exterior and interior 3, 4, 6, 9, 12, 16, 19, 25,32mm

Thicker panels are available from some manufacturers for special applications e.g. 150 mm thick plywood used as bridge decking.

Larger panel sizes can be produced by scarf-jointing.

Floor Span:

Designed for use as subfloor/underlayment. Provides concentrated and impact load resistance and smooth surface for application of pad and carpet. Available in square edge or T&G.

Sheathing Span:

Appropriate for a range of construction and industrial applications, but specifically designed for wall and roof sheathing and subfloor.

Handling and Storage:

Like all building materials plywood panels should be stored and handled correctly to prevent damage and assure reliable performance. Edges and ends of all panels must be protected. Panels to be moved by forklift should be placed on pallets or bunks to avoid damage by fork tines. Panels to be transported on open truck beds should be covered for protection from weather exposure. Plywood panels should preferably be stored under a roof, with the top panel in the stack being weighed down to minimize warpage from humidity. If moisture absorption is expected, the steel banding on panel bundles should be cut to prevent edge damage.

GRADE A

High quality clear veneer with minor filled splits

Textured exterior cladding

Interior wall and ceiling linings

Furniture and Joinery

GRADE B

Appearance grade with minor repairs. Suitable for high quality paint finishing.

Furniture and Joinery

Concrete formwork

Primary Sheathing

Signs

Engineered Components

GRADE C

Concrete formwork

Gussets

Roof decking

Flooring

Bins, Boxes, Crates

Sub-Sheathing

Stressed skin panels

Hoardings

GRADE D

Unfilled veneer allowing open holes to a maximum of 75mm diameter. Splits and solid knots also allowable.

For structural applications where appearance is not a primary consideration.

Structural Components

Beams, Portals

Roofing

Bracing

Utility Buildings

GRADE PG

Non standard, non structural veneer with unrestricted holes, knots, splits and rough grain.

Temporary Security Covers

Pallets

General Packaging

Fillets/Liners

Crates

When specifying plywood, the following information needs to be supplied:

Number of panels

Length , width and thickness (mm)

Plywood type (eg. structural)

Face and back grades

Glue bond type

Preservative treatment level if required e.g. Losp , ACQ or CCA

Plywood is specified by both faces, two letters; the first being the face veneer quality and the second the back veneer quality. This allows some economy as one face of a plywood sheet is often hidden from view and a lower grade face can be specified for the non visible face. For example, AD calls up a plywood with the front face A grade and the rear face D grade. Plywood flooring is typically specified as CD.

Other examples;

AA for marine plywood

AD for wall cladding where only the front face is visible

BB for high grade paint finish

CD for structural plywood flooring

DD for hidden structural bracing

It should be noted that a plywood with D faces is not necessarily structurally inferior to one with A faces as the terms relate to aesthetic quality. The structural attributes of the plywood are allocated via a stress grade.

Bond Quality

Type A bond: is a permanent bond, recognisable by its black colour, which will not deteriorate under wet conditions, heat or cold, and is required for all structural and marine plywoods, and in areas around sinks, vanity units and laundry tubs.

Type B bond: is appropriate for a maximum of two years exposure for applications such as formwork or for semi-exposed external door skins.

Type C bond: is suitable for non-structural interior applications, free from wet or damp conditions.

Type D bond: is appropriate for non-structural internal low-humidity environments such as internal panelling.

Stress Grades

The characteristic strength and stiffness values of structural plywood are allocated via the F- grade classification system and are given in AS 1720.1 SAA Timber Structures Code, Section 5 and AS/NZS 2269, Plywood – Structural. Refer to section on engineering design.

It should be noted that although the F-Grade characteristic strength and stiffness values of structural plywood and structural timber are the same for bending, tension, compression and modulus of elasticity; shear capacity of structural plywood is superior and Modulus of Rigidity is marginally reduced.

It should also be noted that the high degree of manufacturing process control and the low co-efficient of variation of structural plywood characteristic properties, resulting from the randomization of natural characteristics in the manufacturing process, gives structural plywood a high degree of structural reliability.

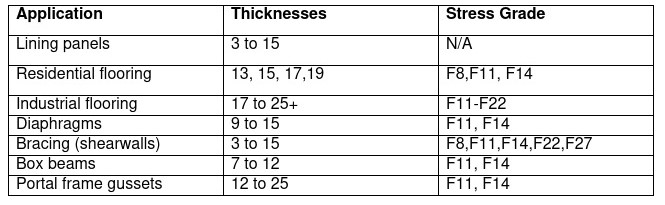

The following table is a guide to the thicknesses and stress grades required for typical applications

Appearance plywood is specified by the required characteristics of the face veneers – species, colour, grain; and by thickness, lamination pattern, type (durability) of glue bond and any treatment.

Structural plywood is specified by thickness, grade, species, type (durability) of glue bond and any treatment.

Please note that Imported plywood to Australia have different grading which can confuse people when ordering.

EG: most use a WBP glue which can be similar to A or B bond in Australia standards.

Also used is terms BC or CPD which in fact is similar to CD to BD grade in Australia standards.

So please ask your supplier and find out if the plywood your requesting is in fact been tested to a standard.

For structural use

The standards I recommend are AS2269 or for a imported ply PS1-09 which is the American and Canadian standard. These standards are very similar just the terms and descriptions vary eg Australia has a F rating where as they use a span table system.