About

We Are a family run Business that aim to help people in the purchase of Building products . With over 40 years expereince in the building supply industry we aim to do our best in helping people find the right product or at least point them in the right direction to companys that can help.

Brochures and links

Pelawan (Northern Box)

INTRODUCTION

The Standard Malaysian Name as well as the ASEAN Standard Name for the timber of Tristaniopsis spp. (Myrtaceae). Vernacular names applied include keruntum (Peninsular Malaysia), malaban (Sarawak), melaban (Sarawak), pelawan-pelawan (Sabah), seluchor (Peninsular Malaysia), selunsor (Sarawak) and selunsor puteh (Sarawak). Major species include T. merguensis, T. obovata and T. whiteana. The sapwood is pink-brown or red-brown and is lighter in colour than the heartwood, which is pink-brown, red-brown or purple-brown, sometimes with a grey tinge.

Also known as Brush box and Yellow panda (Australia); Rong leang (Cambodia); Balaban, Pelawan, Pelawan Merah, Pelawan Talang, Radja, Tabi and Wawako (Indonesia); Duakyat (Myanmar); Papua New Guinea swamp box and Swamp mahogany (Papua New Guinea); Malabayabas, Taba and Tiga (Philippines); and Tamsao-nu (Thailand).

DENSITY

The timber is hard to very hard and heavy to very heavy with a density of 915-1,250 kg/m3 air dry.

NATURAL DURABILITY

The timber is reputed to be very durable. Related species have been tested in other countries and found to be very durable under all conditions and even resistant to termite and marine borer attacks (Wong, 1976).

TEXTURE

Texture is rather fine and even, with interlocked, sometimes wavy grain.

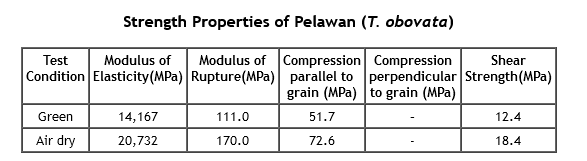

STRENGTH PROPERTIES

The timber falls into Strength Group A (Abdul, 1985)

ngth Prope

MACHINING PROPERTIES

The timber is reported to be difficult to saw but can be finished to a very smooth surface.

AIR DRYING

The timber seasons moderately slowly. 40 mm thick boards take approximately 5 months to air dry. Drying defects are not particularly serious and only minor defects such as light end-checking, splitting, etc., have been recorded.

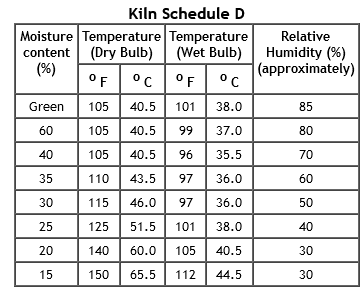

KILN-DRYING

Schedule D is recommended. The timber is liable to cupping and end-checking. 25 mm thick boards take approximately 9 days to dry.

SHRINKAGE

Radial shrinkage averages 2.6%, while tangential shrinkage averages 3.8%.

USES

The timber is suitable for all heavy constructional works, posts, beams, joists, rafters, tools handles (impact), heavy duty furniture, vehicle bodies (framework, planking and floor boards), door and window frames and sills, columns (heavy duty), staircase (carriage, newel, riser, stringer, tread, bullnose, round end and winder), boat framing and other marine construction. It should also be suitable for heavy-duty flooring.

REFERENCES

Abdul Khalid Che Din. 1985. Malaysian Timbers - Pelawan. Malaysian Forest Service Trade Leaflet No.100. The Malaysian Timber Industry Board and Forest Research Institute Malaysia, Kuala Lumpur. 5 pp. Menon, P. K. B. 1986. Uses of Some Malaysian Timbers. Revised by Lim, S. C. Timber Trade Leaflet No. 31. The Malaysian Timber Industry Board and Forest Research Insitute Malaysia, Kuala Lumpur. 48 pp. Wong, T. M. 1976. Wood Structure of the Lesser Known Timbers of Peninsular Malaysia. Mal. For. Rec. No.28. Wong, T. M. 1982. A Dictionary of Malaysian Timbers. Revised by Lim, S. C. & Chung, R. C. K. Malayan Forest Record No. 30. Forest Research Institute Malaysia Kuala Lumpur. 201 pp.

Gallery